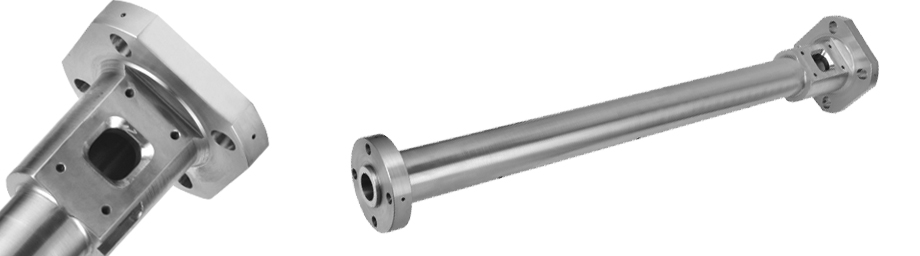

TIZA can manufacture Extruder Barrels either in nitriding steel (SACM645) or with a bimetallic bore.

Nitrided barrels can be manufactured with any size bore and offer a good all round performance for general purpose use.

The nitriding process we use are the gas nitriding and plasma nitriding which produce a nitrided layer that penetrates to a minimum depth of 0.6mm and a hardness of approximately 65/70 HRC.

TNB160: For General Purpose Use

Composition: Nickel-rich iron-boron alloy.

Cost-effective choice for extrusion of unfilled or lightly filled polymers having good thermal stability.

Outlasts generic competitive barrels in comparative testing.

Bimetallic barrels are more suitable for higher wear & corrosion applications. There is several bore linings available depending on the application. (please see the table in Bimetallic Barrels)

Bimetallic barrel blanks are manufactured using a centrifugal-casting process. The term Bimetallic indicates the fusion of two different metals in a high-temperature furnace that subjects the two metals to temperatures of more than 1100°C.

High revolution spinning of the white-hot cylinder fuses the inlay alloy to the bore wall. Subsequent carefully controlled cooling creates a super-hard, highly uniform lining in the cylinder bore, which is then honed to the finished internal diameter. The finished bore lining is at least 1.5 mm thick and on most coatings is 2/2.5 mm thick.

TCZ-900: Our best extrusion barrel

Composition: Tungsten carbide particles uniformly dispersed in a corrosion-resistant nickel alloy matrix.

Outstanding resistance to both abrasive wear and corrosion

Essential for extrusion of hard-to-melt materials such as HMW-HDPE or LLDPE and of highly filled abrasive materials such as those containing 25% or more of mineral fillers (calcium carbonate etc.) or glass fibers.

Resists corrosive attack by aggressive volatiles released by polymers or additives.

Industries Served:

Cable and Wire, Blown Film and Cast Film Extrusion, HDPE/PP/PVC Pipes and Fittings, uPVC Profiles and fittings, Filament Extrusion, Plastics Reclaim and Recycling, Plastic Sheets and Boards, Extrusion Coating, Medical Tubing, and etc.

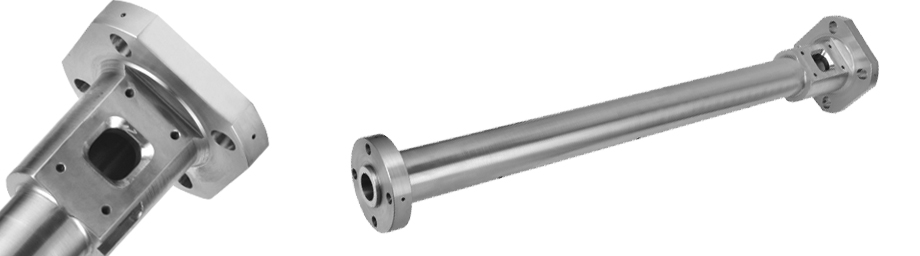

Nitrided barrels can be manufactured with any size bore and offer a good all round performance for general purpose use.

The nitriding process we use are the gas nitriding and plasma nitriding which produce a nitrided layer that penetrates to a minimum depth of 0.6mm and a hardness of approximately 65/70 HRC.

TNB160: For General Purpose Use

Composition: Nickel-rich iron-boron alloy.

Cost-effective choice for extrusion of unfilled or lightly filled polymers having good thermal stability.

Outlasts generic competitive barrels in comparative testing.

Bimetallic barrels are more suitable for higher wear & corrosion applications. There is several bore linings available depending on the application. (please see the table in Bimetallic Barrels)

Bimetallic barrel blanks are manufactured using a centrifugal-casting process. The term Bimetallic indicates the fusion of two different metals in a high-temperature furnace that subjects the two metals to temperatures of more than 1100°C.

High revolution spinning of the white-hot cylinder fuses the inlay alloy to the bore wall. Subsequent carefully controlled cooling creates a super-hard, highly uniform lining in the cylinder bore, which is then honed to the finished internal diameter. The finished bore lining is at least 1.5 mm thick and on most coatings is 2/2.5 mm thick.

TCZ-900: Our best extrusion barrel

Composition: Tungsten carbide particles uniformly dispersed in a corrosion-resistant nickel alloy matrix.

Outstanding resistance to both abrasive wear and corrosion

Essential for extrusion of hard-to-melt materials such as HMW-HDPE or LLDPE and of highly filled abrasive materials such as those containing 25% or more of mineral fillers (calcium carbonate etc.) or glass fibers.

Resists corrosive attack by aggressive volatiles released by polymers or additives.

Industries Served:

Cable and Wire, Blown Film and Cast Film Extrusion, HDPE/PP/PVC Pipes and Fittings, uPVC Profiles and fittings, Filament Extrusion, Plastics Reclaim and Recycling, Plastic Sheets and Boards, Extrusion Coating, Medical Tubing, and etc.