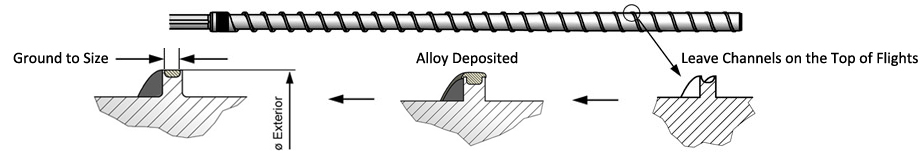

Base Material: 38CrMoAlA JIS SACM645 Hard Surfacing: Nickel-Base Alloy, Co-Base Alloy

Special Coatings: Ti-Coating, Hard Chrome Plating, Carbide Coating

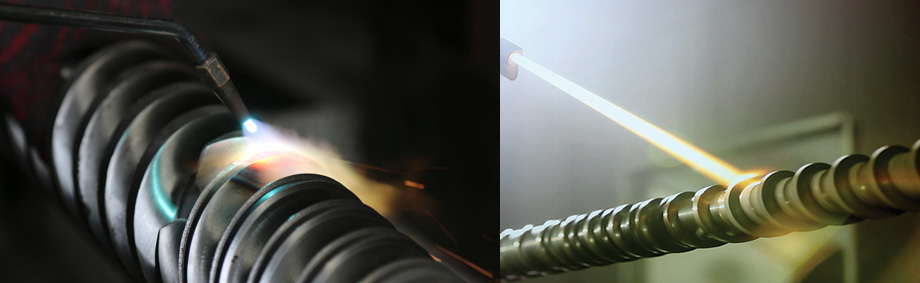

Manufacture Methods: PTA/HOVF

Hardness HRC 50 / 60;

Hardness layer reaches 1.5 m/m thickness;

Hardness does not decrease with depth;

Hardness does not decrease under normal temperature;

Outstanding wear-resistance and corrosion-resistance;

Abrasion wear resistance on the hardened layer is 2~3 times higher than that treated by conventional heat treatment.

The PTA(Plasma Transferred Arc) powder plasma welding applies the positive and negative electrodes of arc welding, allowing the welding path to be completely welded with the base material. The minimum possibility of the welding path becoming less rigid fully prevents the welding layer from peeling off – thereby effectively upgrading the life time of the screws.

PTA utilizes Nickel-based alloys and Cobalt-based alloys and its chemical composition includes Ni, WC, CO, Fe, Si, B, Cr and C.

Keywords: bimetallic screws, bimetallic barrels, bimetallic cylinders and screw hardfacings, high wear screws and barrels, wear protection, bimetal barrels, bimetal screws

Keywords in Various Languages: Roscas de Plastificação Bimetálica, Roscas e Cilindros Bimetálicos, Roscas de Plastificação para Injetoras, Extrusoras e Sopradoras de Plásticos; husillos bimetálicos, husillos para la inyección, husillos nitruración, husillos nitrurados como bimetalicos, husillos para la extrusión, husillos y cámaras para diferente tipo de maquinaria de plástico (inyección, soplado y extrusión); układy plastyfikujące,ślimaki azotowane, wzmocnione, chromowane; ślimaki i cylindry do wtryskarek i wytłaczarek,